COAL, FLY ASH PROCESSING

ADMIN AMERICAN/2018/09

Vostosun provides customers with fly ash drying solutions for coal plants. Fly ash is the primary solid waste produced by coal plants. It contains SiO2, Al2O3, FeO, Fe2O3, CaO, TiO2, etc. Therefore, fly ash has a wide range of applications, such as a primary ingredient of bricks, agricultural fertilizer modifiers, adsorption materials, and environmental protection materials. It also can be used in admixtures of concrete, thus lowering the cost of cement and fine aggregate.

Associated Equipment

Vostosun provides customers with fly ash drying solutions for coal plants. Fly ash is the primary solid waste produced by coal plants. It contains SiO2, Al2O3, FeO, Fe2O3, CaO, TiO2, etc. Therefore, fly ash has a wide range of applications, such as a primary ingredient of bricks, agricultural fertilizer modifiers, adsorption materials, and environmental protection materials. It also can be used in admixtures of concrete, thus lowering the cost of cement and fine aggregate.

Associated Equipment

1. Hammer Rock Crusher

2. Vibrating Screen

3. Spread Device

4. Coal Injection Machine

5. Pulverized Coal Burner

6. Combustion Chamber

2. Vibrating Screen

3. Spread Device

4. Coal Injection Machine

5. Pulverized Coal Burner

6. Combustion Chamber

7. Rotary Drum Dryer

8. Three Drum Rotary Dryer

9. Rotary Drum Cooler

10. Cyclone Dust Extractor

11. Bucket Elevator

12. Belt Conveyor system

8. Three Drum Rotary Dryer

9. Rotary Drum Cooler

10. Cyclone Dust Extractor

11. Bucket Elevator

12. Belt Conveyor system

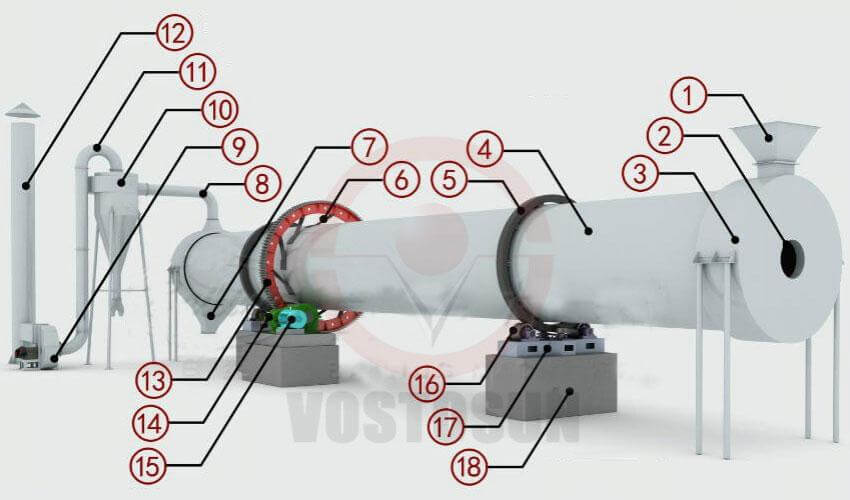

Remarks:

1. Feeding Mouth

2. Heat Source Inlet

3. Feeding End

4. Rotary Dryer

5. Rolling Ring

6. Spring Plate

2. Heat Source Inlet

3. Feeding End

4. Rotary Dryer

5. Rolling Ring

6. Spring Plate

7. Discharging Mouth

8. Dust Collecting Pipe

9. Fan

10. Cyclone Dust Collector

11. Air Inlet Pipe

12. Chimney

8. Dust Collecting Pipe

9. Fan

10. Cyclone Dust Collector

11. Air Inlet Pipe

12. Chimney

13. Gear Ring

14. Speed Reducer

15. Motor

16. Supporting Roller

17. Supporting Roller Bracket

18. Foundation

14. Speed Reducer

15. Motor

16. Supporting Roller

17. Supporting Roller Bracket

18. Foundation

The fly ash drying process provided by Vostosun contains three steps: spreading, drying and cooling. First, spread the wet fly ash (20-30% moisture) from feeder in the feed section of the dryer. Next, the small block fly ash can be distributed in the whole drying space by the lifting plate inside the dryer cylinder, and evaporated by the hot blast stove. Last, the dried material can be cooled to the proper temperature by the rotary cooler, and can be sent to the product warehouse through the discharging mouth by the conveyor system.

Customer Case

Procurement equipment: rotary dryer

Processing materials: fly ash

Place: Shanxi in China

Features: The thermocouples are arranged on the feeding and discharging end in the dryer to control the temperature. Digital display, and range is 250-380 ℃.

Procurement equipment: rotary dryer

Processing materials: fly ash

Place: Shanxi in China

Features: The thermocouples are arranged on the feeding and discharging end in the dryer to control the temperature. Digital display, and range is 250-380 ℃.